|

Marcus Vinicius C. de Melo e Silva Marcus Vinicius Ribeiro Reviewed by |

|

Introduction

Industrial automation has given rise to additional gains in different industrial processes, especially the use of position transmitters in sugarcane juice extraction.

The growth of environmental responsibility and the reduction of sugarcane burn during the harvest process, and mechanized harvesting brings the stalks to crushing as pre-cut sections. This results in a denser raw-material and allows the use of position transmitters in the automation of the continuous outpouring of the cane feeding tables.

The constancy of the discharge reflects on the first Chute Donelly level control, contributing to improve the extraction, as this crushing tandem accounts for 70 percent of the extracted total. The rest is left for the subsequent tandems that control the flow of the a water, the mechanical adjustment of the rolls, the speed of rolls in function of the Chute Donelly level and the pressure exerted on the tandem upper roll.

The upper inlet roll moves nearer or farther from the bottom roll, according to the quantity of cane entering the system. This movement is called fluctuation and is done in a tilted position in order to enable easier displacement for the upper bearing. This movement cannot be too high or the cane crushing will be weak or inexistent; if too low, the rolls will be forced unnecessarily and will wear down its grooves, which could cause stops by clogging, with the fibers remaining inside the equipment parts.

The roll is moved through hydraulic heads fixed to the castle on both sides. The heads are activated by means of pistons that push the roll against the incoming cane depending on its quantity.

Related Variables

There are many factors that influence crushing efficiency, the following being:

- The quantity of cane,

- The area of contact, weight and grooves of rolls,

- The opening between rolls;

- The pressure exerted on the upper roll,

- The preparation of the cane,

- The imbibition water flow.

- The sugarcane quality – depends on the climate conditions and also on the agricultural sector´s responsibility. The fiber contents, for example, increase during the harvest and can reach 15 percent, approximately. To compensate this variation, the cane preparation undergoes maintenance and adjustments during the crop interval as to open the cane cells the maximum possible before crushing starts. This enhances the importance of the continuous cane feed for the control of the mattress height during the process.

- The contact area, weight and roll grooves – are milling parameters designed for the optimization of the milling process. In addition, periodically the roll grooves are sharpened to avoid the cane to slide and the bagasse is conveyed with efficiency to the next tandems. If the roll is worn out, the extraction efficiency diminishes. Measuring this efficiency is one of the main purposes of industrial automation, by enabling the immediate action of mechanical correction.

- The space between rolls is determined before milling starts. This space is based on studies taking into consideration the type of mills and parameters such as the surface of the cane thresher, its design and the distance from the upper roll to the area of the flange covering the end of the rolls. The adequate gap between rolls will avoid, e.g., the loss of milling process efficiency.

- Roll Pressure – The pressure on the upper roll is regulated by the hydraulic head. The reason for it is that during the milling there are variations on the quantity of cane passing through the rolls, as well as on the cane fiber contents along harvest. This constantly changes the cane pressure on the roll, which should provide balance for better milling during the process.

A simple examination can prove that the milling yield is directly linked to two factors:

1 – The counter-pressure of the cane mattress on the upper roll;

2 – The pressure exerted by the hydraulic head;The first variable is attenuated by the correct cane preparation through choppers and threshers and the proper feeding on the first crushing tandem. The mass must be homogenized to correct irregularities caused by twisted stems. This can only be done before the mass feeds the first Chute Donelly through the feed duct.

The second variable is directly related to the fluctuation of the upper roll. This space is on average between 20 and 30 mm and must be the same on both sides of the upper roll in a same set. Monitoring this gap is essential for a more efficient milling and the mechanical protection of the entire equipment. This monitoring and that of the hydraulic pressure, with possible correction, are of great importance to complement the extraction efficiency.

- Cane preparation – The cane is prepared through a defibration process that is the main point for establishing the optimum juice extraction from the stalks to be crushed. Therefore, it determines the adequate pressure on the rolls, in spite of which there may occur clogging between the rolls, if the volume of the cane passing through is larger than their crushing capacity. Hence, the control of the Donelly level working on the rotation of the tandems has an additional factor: the fluctuation of the upper roll.

- Control of the Imbibition Water Flow – If the cane is too wet it may produce clogs that makes milling more difficult. If it is too dry, milling is more efficient, but, on the other hand, the extraction of saccharose is impaired. So, it is extremely important to keep the adequate flow and temperature of the imbibition water under control, for a good extraction of saccharose without cloggings.

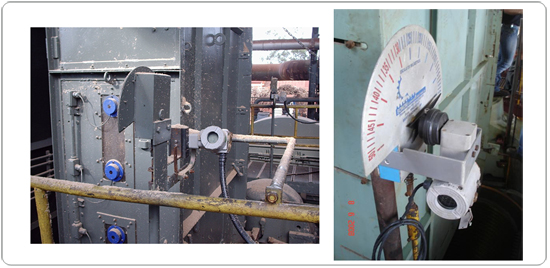

A conventional method for checking the roll fluctuation is through pointers coupled to the upper roll. Right above the rolls there is a shaft and at the other end there is a spring attached to the pointer, as shown on Figure 1.

The displacement indicated varies from one application to another. In some cases it reaches 25 mm upwards, a value corresponding to an oil pressure of 2.500 lb on the hydraulic head. This application supports up to 3.000 lb of pressure on the hydraulic head, which is controlled by an oil pump. Above that level, the right measure is to control the cane volume in the Chute Donelly, thus avoiding unexpected breaks due to large volume.

FIGURE 1 – Conventional Spring-Pointer for indication of Upper Roll DisplacementThe entire control is visual/manual, which involves considerable correction time, in terms of getting the right perception, problem report, displacement of the pressure control panel, pump response and checking time.

SMAR POSITION TRANSMITTER

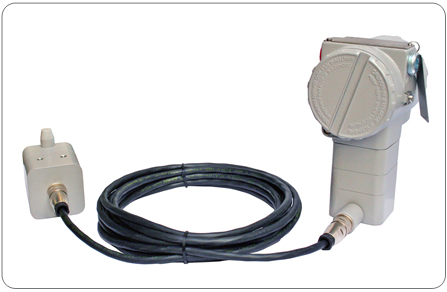

FIGURE 2 – SMAR Position Transmitter on a Control ValveSMAR position transmitters TP301 (4 a 20mA and HART Tecnology), TP302 (Fieldbus) and TP303 (PROFIBUS), are used to control and monitor any kind of displacement, be it linear or rotary. The position is measured with basis on the Hall Effect principle, with a magnetic sensor designed to receive the signal generated by the movement of a magnet.

Mounting the SMAR Position Transmitter depends on the movement to be applied, be it linear or rotary. Measuring the displacement of any mobile part of a device requires the fixation of the magnet and the position transmitter on any type of support. The magnet should induce its magnetic field to the transmitter sensor during the entire course that will be measured.

The Hall Effect position sensor supplies an output voltage proportional to the variation of the magnetic field applied. There are two magnets reversely polarized working directly on that sensor. The measuring ranges vary from 3 to100 mm for linear displacements and 30 to 120º for rotary ones.

FIGURE 3 - SMAR Position Transmitter with Remote SensorIn addition to the conventional models, SMAR has the remote position sensor version, for applications on high temperatures, great vibrations or sites with difficult access. The cable lengths for the remote sensor are 5, 10, 15 and 20 m.

Application

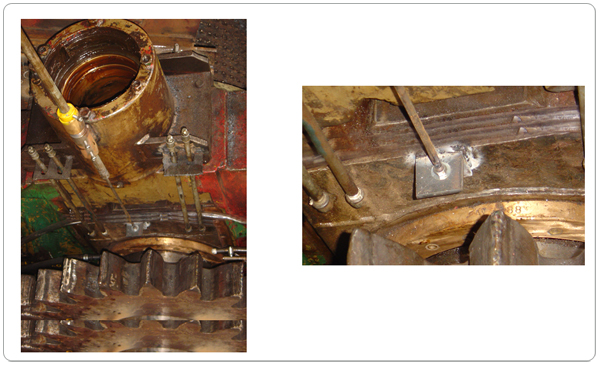

Similarly to the pointer, the Position Transmitter needs a support compatible with the vertical roll movement. Its base, on most application seen on the field, keeps direct contact with the upper roll bearing, as shown on Figure 4. Hardly this support is located on the top of the roll, as this wears down both the roll and the shaft.

FIGURE 4 – The shaft support is typically attached to the upper roll bearing. See detail on the right.

FIGURE 5 – Pipe wrapping the shaft, the magnet attached to it and the TP fixed on another support

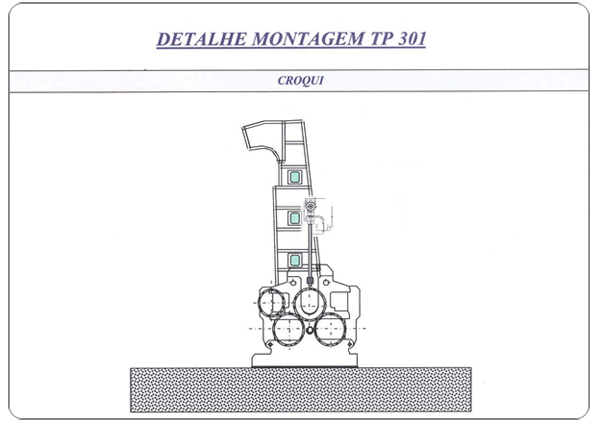

FIGURE 6 - Application schemeThe Position Transmitter is fixed on another place, according to the shaft length, with its Hall sensor lined up with the magnet, as seen above. The location of the Position Sensor varies from plan to plant: the external part that covers the hydraulic head, Chute Donelly, handrail of the catwalk over the mills, etc. This procedure is applied on both sides of the upper roll to adjust the horizontal level.

It is recommended the use of a pipe on the shaft to avoid side displacements. The magnet is installed on the other end of the shaft, as shown on Figure 5.The shaft moves up or down with the roll movement and the Position Transmitter responds to this displacement in the desired unit, including percentages, as shown on the figure below.

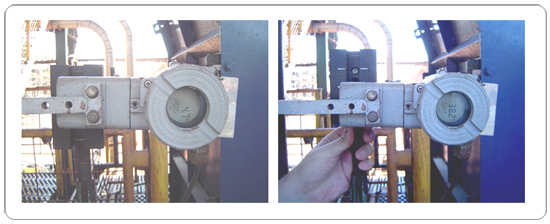

FIGURE 7 – Shaft being displaced, with indication on mechanical display

FIGURE 8 – Linear and Rotary TP with mechanical indicatorApplications commonly combine the Position Transmitter and the mechanical indicator for measuring linear or rotary displacements, making use of the shafts and couplings already installed, as shown on Figure 8.

In the present case, the same structure serves two primary objectives:

1) Keep an adequate cane volume passing through the roll, for better crushing;

2) Correct the imbibition water flow.In both instances, the position transmitter supplies remote setpoint for the mill tandems and the imbibition water control.

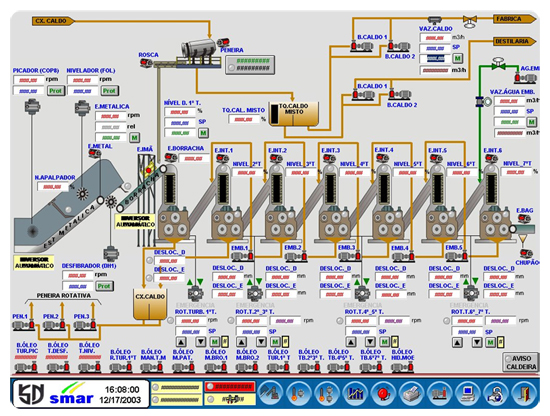

The imbibition water flow using only the pre-analyses milling conditions for a given crop through a local setpoint results in losses due to the excess or lack of the liquid on the process. The flow measurement, in this case, may be done by primary elements such as the orifice plate, where the difference of pressure between the sides of the plate will be converted into flow signal. Also magnetic meters are applied, using the variation of the magnetic field crossed by the fluid to measure the flow.Figure 9 shows the screen of a supervisory system on top of a mill, with the control of the imbibition water flow, the indication of the upper roll displacement, indicating the right and left sides. Also are shown the remote rotation setpoints of the crushing tandems and the loop with sensor on the feeding table.

FIGURE 9 – Supervisory indicating the control setpointsThe SMAR Position Transmitter configures the upper roll displacement range up and down. On the field, the average displacement does not exceed 30 mm.

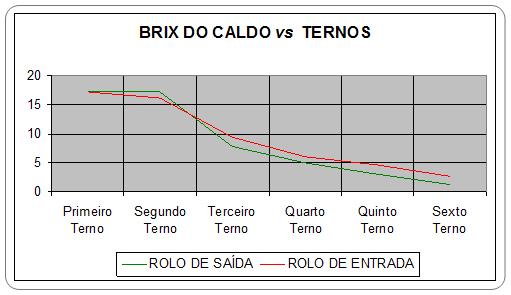

In this application, the Position Transmitter offers conditions for correction of the hydraulic head pressure, while observing the sugar juice brix curve, which is measured on two or three points. For example, before the input roll, the juice reserved for the related crushing tandem, and the output roll. The purpose is to analyze the extraction curve and compare it with the ideal one, which varies from plant to plant.

FIGURE 10 – Juice Brix Curve for each crushing tandem

Therefore, if any irregularity occurs on the roll fluctuation, whose level is measured by the SMAR Position Transmitter, the correction will be made by automatic controls on the milling area. In addition to the imbibition water flow already mentioned, there are the following factors:

- Cane Feeding– controlled since the measurement of the first Chute Donelly level. It works on the speed of the rubber and metal conveyor belt, favoring better protection for the choppers and defibers against cloggings, reducing their wear. The speed of the rubber and metal conveyor belt is controlled since the first Chute Donelly level.

- Electric Turbines and Motors Speed – controls the speed of the startup tandems, the second tandems and the following tandems. The variable measured for this control is the level of cane on the Chute Donelly of the related crushing tandem.

It also improves the control of the imbitition water flow, a parameter directly related to the Chute Donelly level and the roll fluctuation

- Juice Box Level - measures and controlsthis level by acting on the electric turbine and motor of the first tandem.

Conclusion

SMAR Position Transmitter presents obvious advantages over the pointer indicator, namely:

- Associated to a control loop it generates a signal equivalent to the upper roll fluctuation level that will be used to reduce or increase the rotary speed of the milling turbines or motors and, consequently, the Chute Donelly level (via SMAR controller). The mere use of the pointer indicator results in delayed corrective measures, which reduces the milling yield.

- The superiority of the Hall Effect position sensor is that it eliminates mechanical contact and increases the reliability on the position measurement, since there will be no loosen nor worn parts that frequently happen in equipments using levers and mechanical devices.

- It also improves the control of the imbitition water flow, a parameter directly associated to the Chule Donelly and the roll fluctuation;

- The precision of the measurements is much higher than the one offered by the pointer, which is subject to mechanical wear

and reduces even more the exactness of measuring.